Co2 Laser Machine Mirror

Molybdenum is a chemical element with the symbol Mo and atomic number 42. The name is from Neo-Latin molybdaenum, which is based on Ancient Greek Μόλυβδος molybdos, meaning lead, since its ores were confused with lead ores.

- MO molybdenum (this element easily forms in hard and stable carbides in alloys and therefore most of the global production of this element (about 80%) is used in steel alloys including high strength alloys and super alloys) directly on the surface of the polished mirror. It is given and its surface lacks a coating layer that is resistant to scrub and has a long life.

- Molybdenum has high surface strength, high melting point, stable chemical properties and corrosion resistance

Mirror features of Co2 laser device

| Abrasion resistant and long life |  |

|

Resistant to high temperature and corrosion. |

| It is also used well in unsuitable environments |  |

Specifications

| the product | Materials used | Diameter | Thickness | Power | ||

|---|---|---|---|---|---|---|

| Co2 laser mirror | Molybdenum metal | mm | inch | mm | inch | watt |

| 15 | 0.59 | 3 | 0.12 | 40~200 | ||

| 19.05 | 0.75 | |||||

| 20 | 0.79 | |||||

| 25 | 0.98 | |||||

| 30 | 1.18 | |||||

| 38.1 | 1.5 | |||||

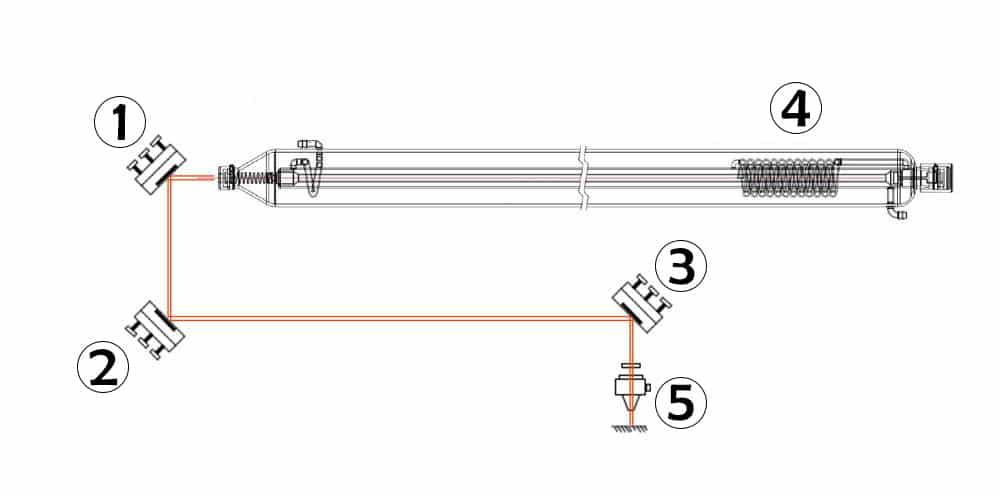

The laser path is irradiated

- #1 mirror

- #2 mirror

- #3 mirror

- Laser Tube

- Fucus Lens

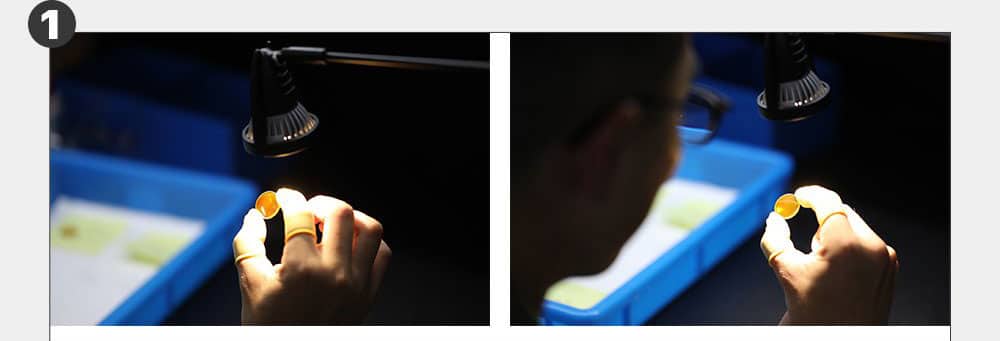

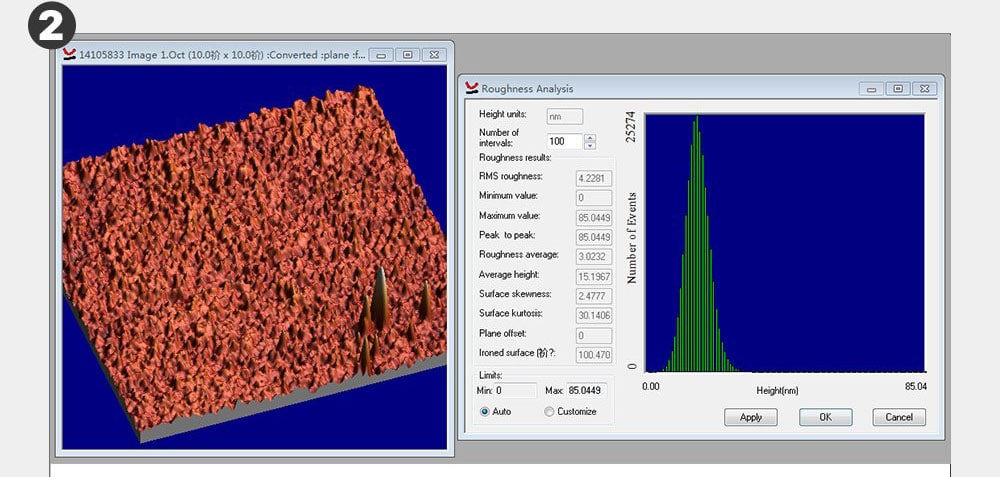

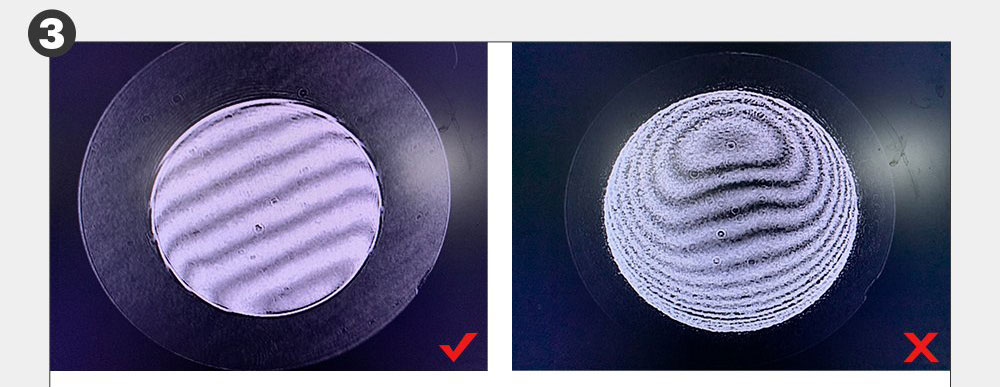

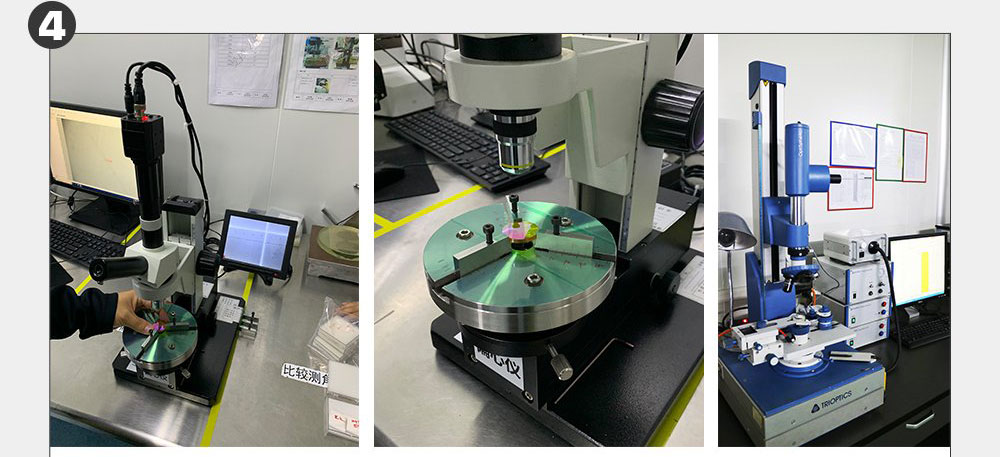

Co2 laser machine mirror test process

Co2 laser machine mirror cleaning tutorial

- Use an air pump to remove any contaminants such as dust, lint particles.

- Pour a few drops of acetone on the lens tissue and wet the full diameter of the optics. (To remove stains and fingerprints)

- Clean the lens with a cotton ball and vinegar. Immediately use a damp cotton swab to remove any acetic acid, then clean with a dry cotton swab. (More suitable for cleaning oil)

Reviews

There are no reviews yet.