What is a earth pit?

In this article from IRANPADRA, we fully state that a suitable earth pit is the protector of the life of someone who works with a laser device, and also how to protect the device by using an earth pit.

Several questions are raised, including: how to install an earth system in a new building. It is stated that IranPadra answer to this question is that there is no need to install an earth in a new building. The work must be considered and activated by the ground system of the building.

The operator who wants to operate in an older building must consider setting up an earth system and take action to build it.

We will continue the process of setting up the earth pit.

EARTH PIT

In electrical engineering, the word earth has different meanings and concepts depending on its uses. Earth in the role of an electrical circuit can act as a starting point according to which other electrical voltages are measured. The term earth is also used to refer to a general path for current to return to its source. The term is also used for a direct ground connection.

An electrical circuit can be grounded for a variety of reasons.

In power circuits, these connections are usually made to increase the safety and protect individuals or devices from the effects of defective conductor insulation.

Grounding in power circuits prevents damage to parts such as circuit insulators by increasing the voltage between ground and circuit and limits this voltage to a certain level.

[aux_quote type=”blockquote-normal” text_align=”left” quote_symbol=”1″ title=”title” extra_classes=””]

Grounding is also used to prevent static electricity surges when transporting flammable materials or repairing electronic equipment.

[/aux_quote]

In some types of telegraphs and transmission networks, the ground alone acts as one of the conductors and is used as a return path to the source, thus saving the cost of creating a separate line to return the current. .

In measurements, the earth is used as a constant electric potential, which determines the potential of each part of the circuit with the earth according to the potential difference. An electric field must have a suitable current transmission capacity in order to be used as a zero voltage source.

The main task of the earthing system is to completely transmit any electric current that enters the system to the ground. The earthing system consists of an earth well and a wire connected to the well. If we connect the body of all electrical appliances, whether industrial, telecommunication, household or in general any kind of electricity consumer, to the ground wire by a wire, we have created an earthing system.

The purpose of creating this system is that if any of the phase wires or neutral wire is connected to the body of the device in any way and the desired electrical circuit leaks current; This current leakage is transmitted to the ground by the ground wire and is prevented from being electrocuted or in some cases connected to the device.

If we want to briefly name the purposes of using the earth system, we will mention the following:

- Protection and safety of human life

- Protection and safety of electrical and electronic equipment

- Provide ideal working conditions

- Avoid contact voltage

- Eliminate excess voltage

- Prevent unwanted voltages and lightning

- Ensure electrical work capability

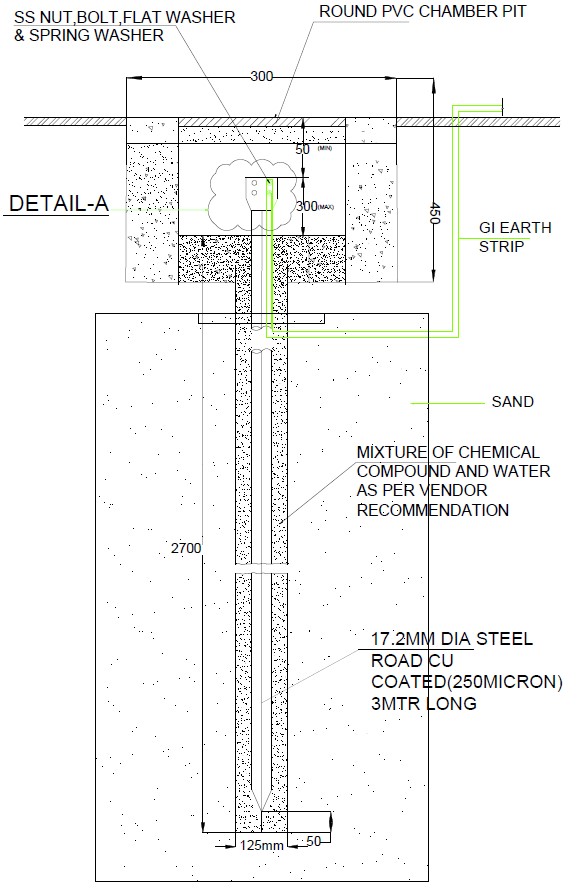

Construction of earth pit

Select the location of the earth well

To choose the right place, it is necessary to dig a well in a place that has the lowest level.

Other reasons for this choice include: the possibility of access to moisture as deep as possible or areas that are more exposed to moisture and water (such as lawns, gardens and green spaces).

Due to the specific resistance of the ground, the depth of the well can be dug from at least 4 meters to 8 meters and with a diameter of about 80 centimeters.

In lands that have lower specific strength due to soil type, such as agricultural soils and clay soils, the depth required for drilling is less and in sandy and sandy loam soils that have higher specific strength, it is necessary to dig wells with greater depth.

Special devices are used to measure the specific strength of the soil.

If we do not reach the depth of 4 meters and it is probable that we will not reach the depth of more than 6 meters, we do not need to dig a well more than 6 meters. In general, a depth of 6 meters and a diameter of about 80 cm is recommended for drilling wells.

Required materials and specifications for earth pit

| 1 |

Lightning rod |

It is 1.5 meters long and 16 mm in diameter, and its material is pure copper and sharp |

| 2 |

Fasten the arrester rod to the ground wire |

To connect the ground wire to the points where the height of the mast is about 20 meters |

| 3 |

Ionolite |

For use in lightning rods |

| 4 |

Fasten the wire to the mast |

Cut the number 50 wire to the required size and string it and use it to connect the earth wire to the mast |

| 5 |

Aluminum or copper straps |

In the sizes of 3 * 30 * 100 mm by using Ionolite to close the lightning rod in the control towers |

| 6 |

Copper wire score 50 |

7 strings |

| 7 |

Cable show score 50 |

To connect the earth wire to the earth busbar inside the site or to connect the legs of the control and self-standing masts to the earth system |

| 8 |

10 atmosphere polyethylene pipe |

To create insulation cover on copper wire in the yard and traffic area |

| 9 |

Clamp polyethylene pipe with screws and dowels |

To connect the polyethylene pipe to the wall |

| 10 |

Cadweld Explosive Powder |

To weld the wire to the plate |

| 11 |

Insulator with screws and dowels |

To connect the copper tray to the wall |

| 12 |

Grade 8 bolts with spring and flat washers |

To connect the copper tray – plate – mast rail |

| 13 |

Fasten the wire to the copper plate |

In order to tighten the wire connection on the copper plate |

| 14 |

Clamp two wires 50 |

To connect two wires with a score of 50 on the ground |

| 15 |

Special plate for connecting the arrester rod to the mast |

Used for 60 meter self-standing towers |

| 16 |

Copper bush for foot rig 3 * 30 * 100 |

To connect the feet of self-standing 60-meter towers to the ground system |

| 17 |

Fasten the lightning rod to the plate |

To connect the arrester rod to the plate in its 60 meter static masts |

| 18 |

Clamp for copper wire |

To connect the wire to the lightning rod |

Connect the wire to the copper plate

Connecting the wire to the copper plate is very important and under no circumstances should this connection be made by just sewing the wire to the plate.

Instead, the wire must be welded to the plate and for more strength, it must be closed and tightened by using 2 wire clamps to the plate (row 15 of the table of required materials).

Use brass or silver welding to weld copper pieces to each other. If this type of welding is not available, Codweld welding is used.

Dig a well

According to the geographical conditions of the region, a well is drilled with a suitable depth and in a suitable place (according to the guide for selecting the location of the well). A groove 60 cm deep from the well to the foot of the rig for the path of the ground well wire to the arrester on the rig is also drilled for the ground wire inside the building.

If the path of the two wires is common, it is better to isolate the path of the two wires. Also, the path of the wires should be the shortest path and the wire of the lightning rod and earth should be as straight as possible and without twisting, and it should not have sharp bends, and if the wire needs to be bent, it should be done more than 50 cm in length.

Filling the earth well

First, about 20 liters of water and salt solution is prepared and poured into the bottom of the well, so that it covers the entire bottom of the well. After 24 hours, the following steps are performed. At a height of 20 cm from the bottom of the well, fill it with clay or soft soil and mix the required amount (about 450 kg, equivalent to 15 bags of 30 kg) with bentonite with water and make a slurry.

The resulting mixture is poured to a height of 20 cm from the bottom of the well.

The thicker the resulting mixture, the better the quality of work.

[aux_quote type=”pullquote-normal” text_align=”left” quote_symbol=”1″ title=”title” extra_classes=””]

Note: If you have started your earth well and you still see problems such as electric shock, ask an expert to check the quality of your well. The low level of earth quality depends on several factors.

Iran Padra Company advises its customers to be aware of their grounding system before installing the device on site. If you have any questions, you can contact the company’s support.

[/aux_quote]